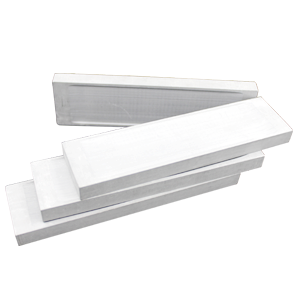

Hexagonal boron nitride can be used to make TiB2/BN composite ceramics, BN ceramic evaporation boat is mainly used in vacuum evaporation packaging materials, metallized capacitor vacuum coating, display coating, bronzing coating, anti-counterfeiting mark coating, reflective coating And paper, textiles, aluminum plating and other industries.

Extraordinary heat resistance

High thermal conductivity

Low thermal expansion, excellent thermal shock resistance

Excellent electrical insulation even at high temperatures

High resistance to molten metal, slag, and glass

Extremely high corrosion and wear resistance

Easy to process to the desired shape and size

Characteristics of BN evaporation boat:

1. The raw materials BN powder and TiB2 powder are of high purity which made by the most advanced powder production process in China. ( BN powder is favored by well-known foreign ceramic company and TiB2 powder meets the requirements of national military products)

2. The unique high purity raw material powder production process has laid the foundation for the quality stability of batch products.

3. International advanced vacuum hot pressing sintering process ensures excellent physical properties of the boats.

4. Years of R&D experience and professional accumulation optimized the formula process, composition, improve the quality of evaporation while extending the service life. Overall displays the best cost performance of BN ceramic evapoation boat.

Specifications:

|

Specifications(mm) |

L |

B |

H |

Cavity size |

L1 |

B1 |

H1 |

|||||||

|

Size |

Tolerance |

Size |

Tolerance |

Size |

Tolerance |

Size |

Tolerance |

Size |

Tolerance |

Size |

Tolerance |

|||

|

105*20*10 |

105 |

±0.5 |

20 |

-0.1 |

10 |

±0.1 |

C |

80 |

±1.5 |

14 |

-0.3 |

1.5 |

±0.15 |

|

|

105*30*10 |

105 |

30 |

10 |

C |

85 |

24 |

1.5 |

|||||||

|

110*7*5 |

110 |

7 |

5 |

C |

60 |

4 |

2.5 |

|||||||

|

110*20*10 |

110 |

16 |

9 |

C |

85 |

10 |

1.2 |

|||||||

|

110*26*10 |

110 |

20 |

10 |

C |

85 |

14 |

1.5 |

|||||||

|

110*30*10 |

110 |

26 |

10 |

C |

70 |

20 |

1.5 |

|||||||

|

120*24*10 |

120 |

24 |

10 |

C |

90 |

18 |

1.5 |

|||||||

|

120*30*10 |

120 |

30 |

10 |

C |

90 |

24 |

1.5 |

|||||||

|

120*35*10 |

120 |

35 |

10 |

C |

85 |

29 |

1.5 |

|||||||

|

125*30*10 |

125 |

30 |

10 |

C |

101 |

24 |

1.5 |

|||||||

|

130*30*10 |

130 |

30 |

10 |

C |

110 |

24 |

1.5 |

|||||||

|

130*35*10 |

130 |

35 |

10 |

C |

110 |

29 |

1.5 |

|||||||

|

130*40*10 |

130 |

40 |

10 |

C |

110 |

34 |

1.5 |

|||||||

|

150*30*10 |

150 |

30 |

10 |

C |

130 |

24 |

1.5 |

|||||||

|

330*25.4*11.5 |

330 |

|

25.4 |

|

11.5 |

|

C |

300 |

|

22 |

|

1.5 |

|

|

Application