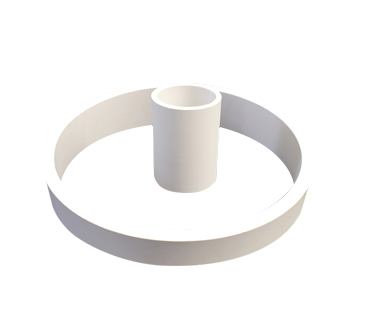

Forming: Cold Isostatic Pressing

Characteristics:

Wear resistance--- The wear resistance of alumina ceramic pipe lining is 10 times higher than that of common pipeline.

Corrosion resistance---Integrated wear resistant alumina ceramic tube can resist the corrosion by strong acid and alkali.

Impact resistance--- Strongly resist to the impact of material with big particles

Smooth inner & outter wall, fluent air flow--- The smooth surface of ceramic pipe lining allows the material to pass freely without hanging and blocking.

Maintenace reduction--- Super abrasion resistance greatly reduces the frequent maintenance cost and labor cost.

Specifications: (Inner Diameter, wallthickness 5-30mm)

|

Φ40 |

Φ81 |

Φ125 |

Φ194 |

Φ307 |

|

Φ50 |

Φ86 |

Φ144 |

Φ200 |

Φ330 |

|

Φ57 |

Φ90 |

Φ150 |

Φ205 |

Φ356 |

|

Φ58 |

Φ96 |

Φ157 |

Φ220 |

Φ417 |

|

Φ60 |

Φ97 |

Φ163 |

Φ230 |

Φ438 |

|

Φ65 |

Φ101 |

Φ172 |

Φ240 |

Φ450 |

|

Φ73 |

Φ110 |

Φ185 |

Φ252 |

Φ498 |

|

Φ76 |

Φ120 |

Φ187 |

Φ295 |

Φ710 |

Applications:

Industry---Material handling

Coal washing ---Media, mixture, slurry conveying

Chemical--- Water slurry containing solid

Coal fired power plant---bottom ash, Pulverized coal, pyrite, srcubber sludge and limestone

Cement---Raw material feeding

Steel plant--- Blast furnace slag, furnace scrubber sludge, oxide scale

Mining---Ore, tailings

Leopoldite plant--- Leopoldite, magnesium sulfate ore

Waste incineration plant--- Slag, incombustible residue

Sand factory--- Sand & stones

Sewage treatment plant --- Sludge, hard slag, water slurry