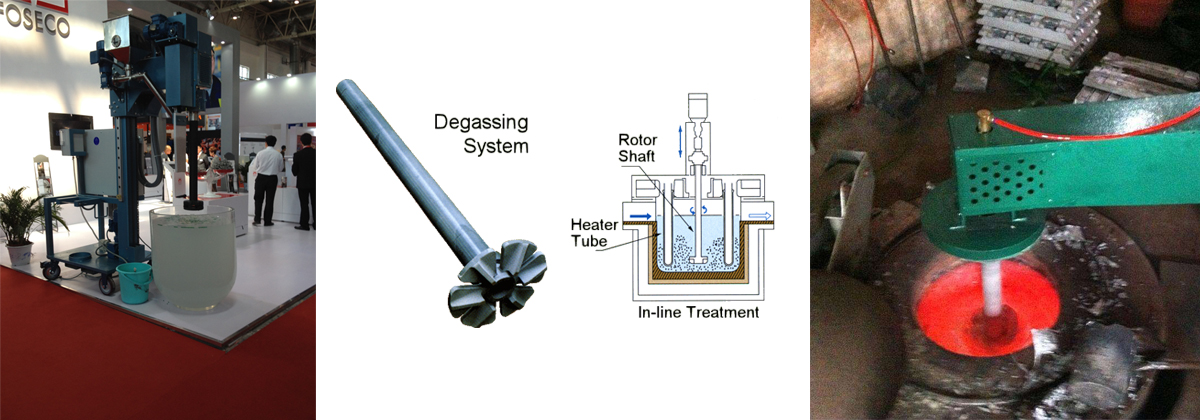

Silicon nitride ceramic is right for making degassing rotor shaft in molten aluminium due to its high density and strength, high temperature resistance, non-wetting and good thermal shock resistance.

For removing the hydrogen in molten aluminium, a silicon nitride pipe is used to feed nitrogen or argon, while silicon nitride degassing rotor is stirring up, dispersing and breaking the gas bubble, and finally the hydrogen is taken out along with the bubbles.

Unlike graphite, silicon ntiride ceramic is hardly oxidized by air at elevated temperatures, which results in longer service life.

High density and excellent high temperature mechanical strength ensure that the degassing rotor shaft runs reliably, stably and lastingly at high speed.

High thermal shock resistance allows repeated insertion and extraction from the molten aluminum during operation without crack or damage, making it easier to use and maintain.

![]()

1. Good density & mechanical strength

2. Good thermal conductivity & thermal shock resistance

3. No wetting by non ferrous metal melts

4. High corrosion and wear resistance

5. Long service life

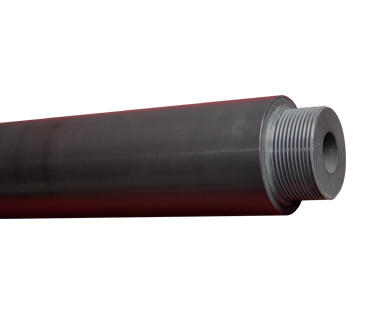

![]() (could process as customers’dimensions)

(could process as customers’dimensions)

|

Type |

Diameter (OD) |

Max. Length |

|

SR DT 220 |

220 MM |

1100MM |

![]()