Silicon Nitride Heater Protection Tube

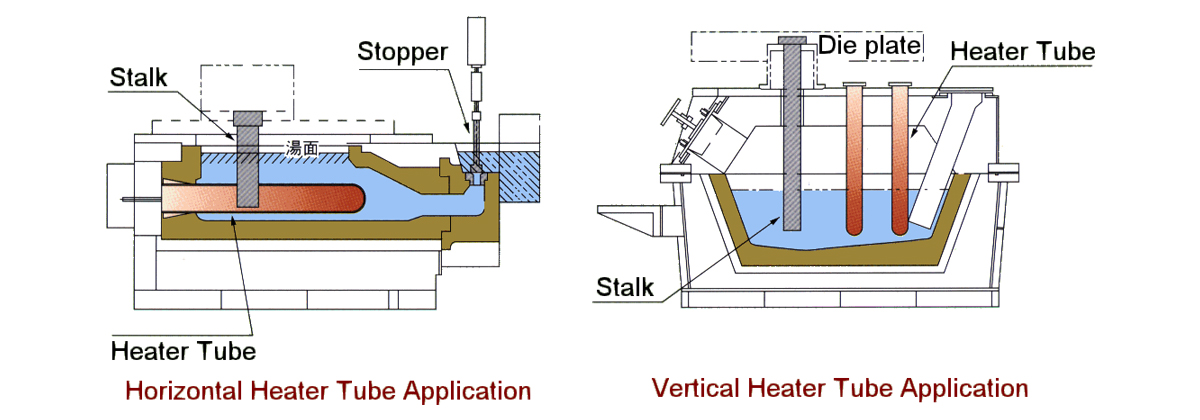

Temperature control is an important factor for obtaining good castings in the process of casting. In order to control the molten metal at the optimum casting temperature, a heating element is used to maintain a constant temperature. Silicon nitride ceramic is used as a heating element protection tube and gas burner protection tube for molten aluminum, and are used in metallurgical industries like aluminum, tin, lead, and zinc.

Excellent high temperature resistance and high temperature mechanical strength make silicon nitride heater protection tube can withstand the heat load of the heating element at high temperature. Even repeated insertion and extraction in the course of operation will not affect the performance of the ceramic heater protection tube.

The excellent thermal shock resistance ensures that the silicon nitride heater protection tube can still work for a long time when the temperature of the molten aluminum increases, the temperature decreases, and the temperature difference between the heating element and the molten aluminum occurs.

Non-wetting by molten metal, good insulation and corrosion resistance allow the heater protection tube to protect the internal heating elements for a long time.

Good thermal conductivity of silicon nitride heater sheath allows the molten metal to be uniformly heated and heated quickly per unit area, which improves the working efficiency in the casting production.

![]()

1. Good density & mechanical strength

2. Good thermal conductivity & thermal shock resistance

3. No wetting by non ferrous metal melts

4. High corrosion and wear resistance

5. Long service life

![]()

|

Type |

Diameter (OD*ID) |

Max. Length |

|

SR HPT 170 |

170*190MM |

1100MM |

(could process as customers size)

![]()